Direct impingement vs gas piston has been a debate in the gun community for a while, with some gun owners preferring the direct impingement system and other owners picking the gas piston.

Each of these systems comes with pros and cons, which can make selecting one a challenge. Today, we will delve a little more into this debate and pit these systems side by side to determine the best one for you! Let’s get started. In this post, you can select the system that is best for your needs.

Whenever a shooter pulls the trigger of a gun, the firing pin hits the cartridge’s primer which creates a controlled explosion that shoots the bullet down the chamber and out of the pistol. The gas created by this explosion is sent into the bolt carrier’s gas key through a gas tube. Afterward, the gas enters the expansion chamber, where it expands and pushes back the bolt carrier. After that, the expended cartridge is ejected from the gun, and a fresh round is inserted into the chamber.

Direct impingement operating systems offer several advantages. To start, they have fewer metal pieces. This means that they have less weight overall. DI weapons also offer less perceived recoil because there isn’t a reciprocating mass that pushes back like in a gas piston pistol. This feature considerably simplifies follow-up shots.

That said, DI firearms aren’t perfect. These systems usually run hot and get dirty because they cycle the action using gas.

The LWRCI direct impingement rifle is a perfect example of a reliable weapon that uses the DI operating system.

Gas piston guns function similarly to direct impingement guns. The only difference between these two methods is how they go about cycling a firearm’s action using gas. Instead of using a gas tube, gas piston systems force gas into a different cylinder. The incoming gas pushes a piston housed in the cylinder, which then pushes the bolt carrier. In comparison, direct impingement involves the gas moving the bolt carrier directly.

Compared to DI guns, gas piston guns operate far more cleanly. This is because they prevent carbon and gas residue from getting around the gun. Gas piston guns can be further classified into two types: long-stroke and short-stroke. Let’s discuss these different types below.

Long-stroke gas pistons are reliable operating systems common on firearms such as AKs, M14s, and the M1 Garand. These kinds of systems are quite reliable.

That said, there are some cons to long-stroke pistons. First off, the gas piston is really large, which causes the weapon to have a strong perceived recoil. The strong recoil makes repeat shots more challenging as a result. Long-stroke pistons also exert considerable force on the barrel due to their reciprocating mass. This may lead to the gun’s barrel shifting during a shot, reducing your shooting accuracy.

You can find short-stroke pistons in the SKS, M1 Carbine, VZ-58, and some AR-15 firearms.

There are a few benefits that short-stroke systems offer over long-stroke and DI systems. To start, they operate far cleaner than DI, much like long-stroke gas systems.

Additionally, compared to long-stroke systems, short-stroke systems have less recoil and greater accuracy since the piston does not cycle the bolt directly. However, this system is less durable and has a shorter operational life than long-stroke gas systems because the piston must hit against a connecting rod to cycle the bolt, thereby causing more wear and tear.

According to reviews, the Patriot Ordinance Factory (POF) is among the most lethal and dependable weapons that utilize gas systems.

Let’s delve deeper into the differences between direct impingement vs. gas-piston operation systems. We’ll compare their reliability, cost, and maintenance needs.

DI systems have proven to be very reliable when properly maintained. However, some issues may arise due to exposure to a lot of dirt and carbon.

Comparatively, gas pistons are also very dependable. They are made with a unique design that keeps the moving parts and gas flow apart, preventing the buildup of dirt and other residue.

This innovative design makes these systems a great option for demanding situations where dependability is crucial, like in the military or law enforcement.

In general, DI systems are cheaper. There are more reasonably priced solutions because these systems are mass-produced and have a more straightforward design. For this reason, DI systems are preferred by shooters on a budget.

On the other hand, gas piston prices are more expensive. The additional components and engineering required for its design increase the overall cost. However, this higher price may be worth it because of the added advantages of using gas pistons, such as better reliability and lower maintenance needs.

If you are willing to pay a little bit extra for these features, buying a gas piston would be a good pickup.

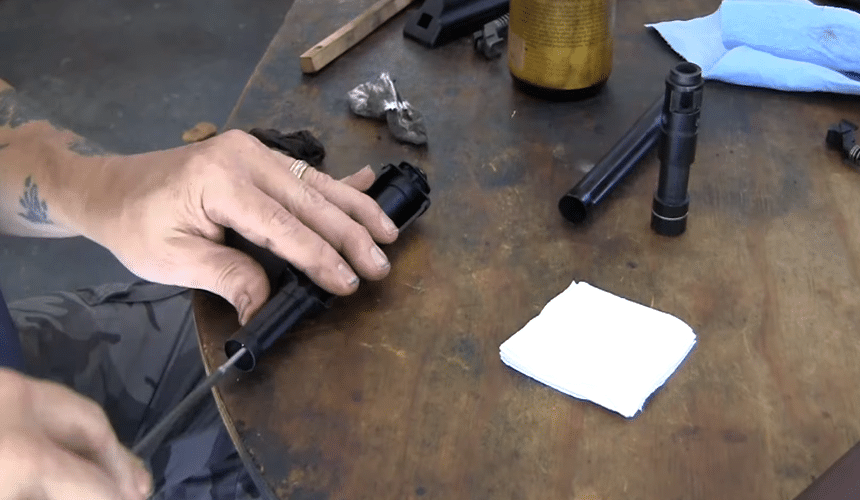

Compared to gas systems, direct impingement systems require more maintenance and cleaning from owners. The gun’s performance may be affected by the buildup of carbon and dirt, which is more likely when internal components are directly exposed to gas flow.

On the other hand, gas piston systems often need less frequent maintenance. Regular cleaning is not as necessary because there is less carbon and dirt buildup. After all, the gas flow is isolated from the moving parts.

DI systems come with their benefits and drawbacks. Let’s look at a few of these direct impingement vs gas piston pros & cons below.

Here we’ll highlight some pros and cons that come with gas pistons.

When it comes to picking between a direct impingement vs piston system, there is no bad pick; your preferred system will depend on what you want. For instance, if you’re on a tight budget, a DI rifle is the ideal choice. On the other hand, a gas piston firearm is a better choice if you want a cleaner weapon and have more money to spare. Ultimately, both of these systems are used on several excellent firearms. So, select the system that best suits your requirements.

Ultimately, both DI and gas piston systems have pros and cons. Therefore, the best system for you will depend on your budget and needs. Choose the gas piston if you want a cleaner weapon that is easier to maintain. However, if you’re on a tight budget, the DI systems may be the best fit. Hopefully, this article resolves the direct impingement vs gas piston debate. Now, go on to your nearest gun shop and make your pick!